At Jackson Spring, we’ve built our reputation over decades by providing highquality, precisionengineered springs that perform reliably in demanding applications. When standard “offtheshelf” springs won’t cut it, a custom spring design becomes essential. In this blog post, we’ll walk you through our streamlined process for custom spring design, highlight key technical considerations, and explain how our engineering expertise ensures you get a component that not only fits but truly performs.

Why Choose a Custom Spring?

Many engineers and procurement specialists start by exploring standard springs — and in many cases, that works fine. But there are several situations where a custom spring is the smarter choice:

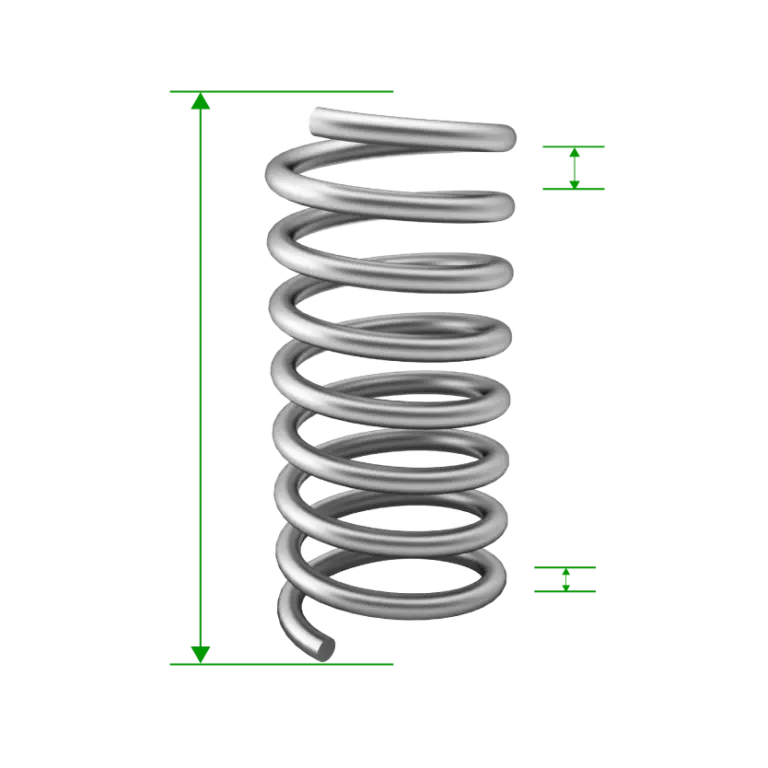

- Your application demands a nonstandard size (diameter, length, wire gauge) or geometry (conical, barrel, dualpitch, wave). Custom springs allow designers to tweak outer diameter, wire diameter, material choice, surface treatments or shape.

- You need a precise spring rate or deflection behavior that a stock spring cannot reliably deliver.

- The environment (temperature, corrosion, fatigue, cycle life) is harsher than typical, requiring material or finish upgrades.

- You’re working with space constraints or integration into a mechanism where packaging (solid height, free length, lateral buckling) matters more than usual.

- Your volume or lifecycle demands mean manufacturability, repeatability and quality metrics are paramount.

At Jackson Spring, we treat custom springs not as a “special order” workaround but as an engineered component that offers the same rigorous analysis and quality control we apply to our standard products.

Our Design & Development Workflow

Here’s how we translate your requirements into a high-performance custom spring:

1. Initial Requirement & Specification Gathering

It starts with you providing the following (as a minimum):

- Load or force (or torque for torsion) requirements and deflection or angular travel (or both).

- Free length (unloaded length) and solid height (if compression) or extended length (for extension).

- Outer diameter (and inner diameter if relevant), wire diameter, number of coils or turns if known.

- Environmental constraints (temperature range, corrosive environment, fatigue cycles, space constraints).

- Any special material, finish or regulatory/industryspec requirement (e.g., RoHS, aerospacegrade).

- Volume expectations (prototype, low run, mass production) and budget/lead time constraints.

2. Conceptual Design & Engineering

Once we’ve understood the specs, our engineers at Jackson Spring create an initial concept. We apply spring theory (such as stress vs. deflection, coil geometry, buckling criteria) to ensure viability. Design support is a key differentiator in custom spring manufacturing.

3. Material & Finish Selection

The right material matters. We choose based on load, fatigue life, environment (corrosion, temperature). Common materials: stainless steel, oil tempered carbon steel, chrome silicon, Inconel or other alloys for high temperature or specialty applications. Surface treatments may include plating, shot peening, passivation or coatings for corrosion resistance or improved life.

4. Prototyping & Testing

For many custom designs we produce a prototype to validate performance under real (or simulated) application conditions. We measure spring rate, deflection vs load, fatigue life, buckling behavior (for long slender springs), and verify geometry in the part’s installed position.

5. Production & Quality Assurance

Once the prototype passes, we move to controlled manufacturing with tooling, repeat processes, and inspection. Critical parameters (free length, solid height, coil count, rate, surface finish) are verified. Quality documentation, traceability and consistency are built into our production.

6. Integration & Support

Because a spring rarely lives alone — it lives inside your assembly — we coordinate with you on installation orientation, interaction with adjacent parts, potential preload or assembly stresses. Our goal: the spring works when it’s installed, not just on the test bench.

Key Design Considerations & Lessons Learned

Here are a few of the most common design pitfalls and how Jackson Spring helps you avoid them:

- Spring rate accuracy vs variability: If the spring rate is too loose or tight, the mechanism may fail or perform poorly. We control wire tolerances, coil count and finish so that actual performance matches design intent.

- Buckling risk in compression springs: Long, slender springs may bend rather than compress cleanly. Tapered or barrel-shaped designs or guide sleeves may help.

- Fatigue life and material selection: Repeated cycles under load can lead to early failure if surface residual stresses or material choice are weak.

- Compression vs. solid height limitations: If a compression spring is compressed past its solid height (coils touching), it may yield and lose life. Designing for proper travel and solid height margin is crucial.

- Environmental and corrosion resistance: If the spring operates in corrosive or high temperature environments, ordinary steel and zinc plated finishes won’t do — stainless steel, special alloys and specialized coatings may be needed.

- Manufacturability and costeffectiveness: Custom springs are more expensive than stock options, so we work with you to balance performance with budget and production volume.

Why Jackson Spring is Your Ideal Partner

With decades of manufacturing experience, Jackson Spring brings:

- Engineering expertise: We don’t just make springs; we engineer them for your exact purpose.

- End-to-end support: From requirement gathering, CAD/model review, prototyping to full production, we handle the workflow.

- Flexible production: Whether you need one prototype or a large production run, we have tooling, automation and quality systems to scale.

- Quality assurance: Traceability, measurement documentation, consistent tolerances and inspections are standard.

- Collaborative approach: We view each custom spring project as a partnership — your mechanism’s success is our success.

When to Reach Out – Your Next Steps

If you’re at the stage where you’ve identified that a stock spring won’t meet your needs — perhaps the load, travel, life or packaging constraints demand something custom — here’s what we recommend:

- Contact us with your initial parameters (load, travel, size constraints, environment).

- Share any application drawings, assemblies or environments we need to know about.

- Let’s discuss prototype timelines, budget and production volume so we can recommend the most cost-effective solution.

- Our engineering team will work back to you with concept, estimated cost/time, material & finish options.

- We’ll move to prototyping, testing and final production once the specification is locked.

In summary, custom spring design may sound like a luxury, but in many applications it’s a necessity to ensure performance, longevity and reliability of the mechanism. At Jackson Spring, we make it straightforward, engineered and dependable. Whether you’re developing new equipment or redesigning an existing mechanism, we’re here to deliver the spring that fits your exact need.