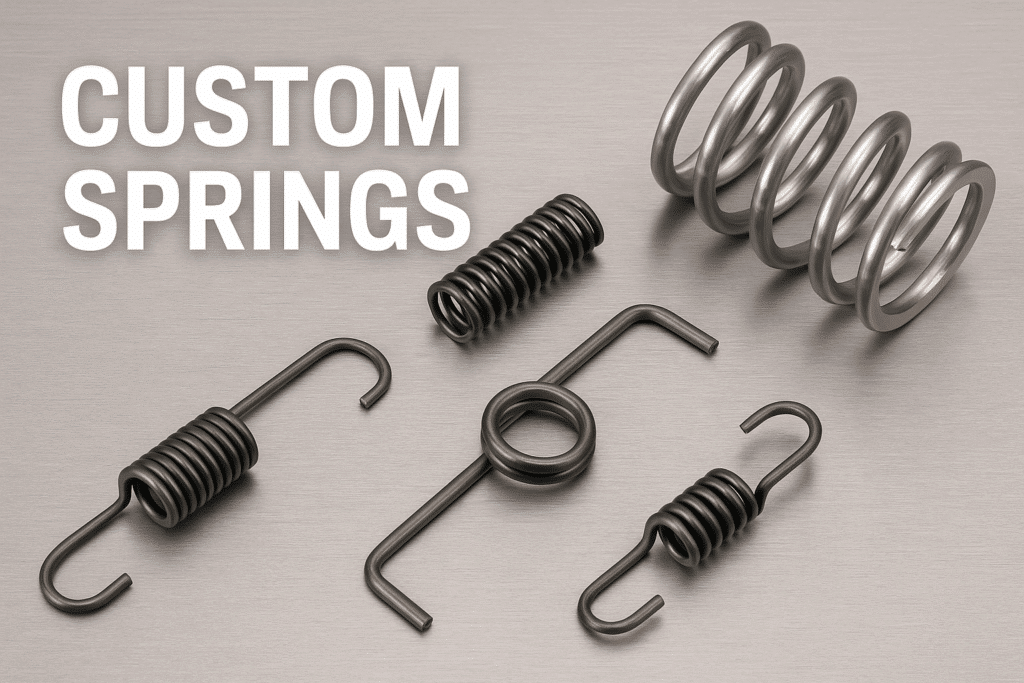

When you’re developing a new product or improving an existing design, selecting the correct spring type is key. Custom spring manufacturing allows you to fine-tune every detail—from force and fit to material and environment—ensuring your spring performs precisely as needed. At Jackson Spring, we specialize in custom compression, extension, and torsion springs tailored for demanding industrial applications.

Compression Springs: Dependable Strength for Axial Loads

Compression springs are open-coiled helicals that resist compression and return to their original shape once the load is removed. They’re the most commonly used spring type in custom spring manufacturing because of their versatility.

Applications: Valves, automotive suspensions, industrial machinery, and electronic assemblies.

Why Choose Custom Compression Springs:

- Optimized spring rate for specific loads

- Adjusted free length and coil count for tight spaces

- Material selection for corrosion resistance or high fatigue life

Extension Springs: Controlled Tension and Smooth Retraction

Extension springs are designed to absorb and store energy by extending. Hooks, loops, or custom ends attach to components that pull away from each other.

Applications: Garage doors, actuators, levers, return mechanisms

Why Choose Custom Extension Springs:

- Preload settings for precise return force

- Hook/end type customization for easy integration

- Designed for specific travel limits and fatigue cycles

Torsion Springs: Precision Torque for Rotational Movement

Torsion springs store energy through rotational force. Their legs or arms apply torque around a central axis, making them ideal for hinges, spools, and latch systems.

Applications: Door hinges, latches, clothespins, and electronic switches

Why Choose Custom Torsion Springs:

- Torque calibration to match application forces

- Leg configuration tailored to mounting needs

- Balanced strength and flexibility for moving parts

Why Custom Spring Manufacturing Matters

Off-the-shelf springs can work in generic applications—but when performance, reliability, or unique form factors are on the line, custom spring manufacturing is the answer.

With custom springs, you get:

- Exact dimensions and tolerances

- Optimized performance in specific operating environments

- Tailored material and coating selections

- Prototyping and testing for performance validation

At Jackson Spring, we don’t just produce springs—we engineer performance. Our in-house tooling, experienced design team, and quality control systems ensure each spring is built to your exact specifications.

Let’s Build Your Next Custom Spring

From initial concept to full-scale production, Jackson Spring is your trusted partner in custom spring manufacturing. We’ll work closely with your engineers to develop springs that meet your technical and budgetary requirements.

Contact us today to discuss your project, or request a quote to get started.