Springs may seem like simple components, but they are the backbone of countless technologies. From your car’s suspension to the life-saving mechanisms in medical devices, springs are everywhere, quietly performing critical roles. What’s exciting is how advancements in spring manufacturing technology are transforming not only the way springs are made but also the industries they serve. For manufacturers and purchasing agents, staying informed about these innovations is crucial to maintaining a competitive edge in today’s rapidly evolving market.

The Unsung Heroes of Modern Technology

At first glance, springs might not seem glamorous. I recall a conversation with a colleague who asked, “Why invest so much in improving spring technology?” I explained that without springs, everything from watches to rockets would be compromised. Springs are everywhere—and the innovations in spring manufacturing technology are unlocking new possibilities that directly impact performance and efficiency.

At Jackson Spring, we’ve witnessed how even minor advancements in spring manufacturing can lead to significant improvements in product durability and customer satisfaction.

The Evolution of Spring Manufacturing

From Tradition to Transformation

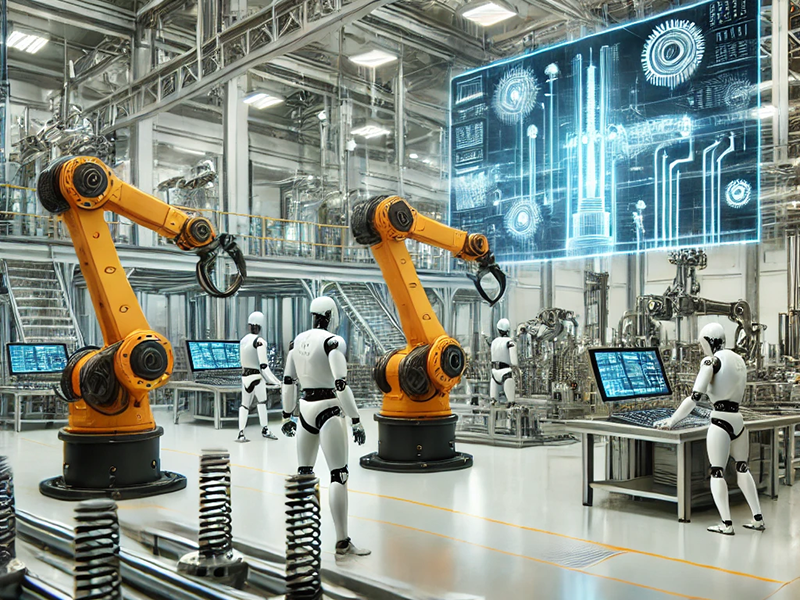

Historically, spring manufacturing was labor-intensive, with skilled workers ensuring precision by hand. Today, advanced machinery, automation, and robotics are redefining the process. Automated coiling machines now produce springs faster, with greater accuracy and minimal waste, meeting the demand for high-volume orders while maintaining quality.

Challenges and Opportunities

Despite its advancements, spring manufacturing still faces challenges:

- Maintaining tight tolerances required by customers.

- Sourcing high-quality, cost-effective materials.

- Meeting the growing demand for custom designs.

However, these challenges are driving opportunities through innovations in automation, materials science, and additive manufacturing.

Cutting-Edge Innovations in Spring Manufacturing Technology

Automation and Robotics

Automation has become the gold standard in spring manufacturing technology. Tasks such as coiling, stress relief, and quality inspections are now handled by robots, ensuring faster production and consistent quality.

For example, an automated coiling system at Jackson Spring allowed us to reduce production times while maintaining impeccable quality standards. This not only benefits us but also allows our customers to receive their orders faster and more reliably.

Advanced Materials

Materials are at the core of innovation in spring manufacturing technology. Lightweight alloys like titanium, alongside composite materials, are replacing traditional steel in industries such as aerospace and automotive. These materials offer higher strength-to-weight ratios and improved performance under stress.

Additive Manufacturing (3D Printing)

3D printing is revolutionizing spring manufacturing by enabling designs that were previously impossible. Manufacturers can now create springs with complex geometries tailored to specific applications, reducing the need for additional processing.

Learn more about the impact of 3D printing in manufacturing.

Smart Springs

The future of springs lies in smart technologies. Springs embedded with sensors can monitor real-time stress, temperature, or load. These are particularly valuable in IoT devices, where data can enhance product reliability and user experience.

Applications Across Industries

Automotive

In the automotive sector, spring manufacturing innovations have led to lighter and more efficient suspension systems, valve springs, and precision components. At Jackson Spring, we work to create custom springs that reduce weight without compromising strength, improving overall vehicle efficiency.

Aerospace

Aerospace applications require springs that perform under extreme conditions, including high temperatures and intense vibrations. Lightweight alloys and heat-treated springs are essential for ensuring reliability and safety in this industry.

Medical Devices

Precision and reliability are critical in medical technology, where springs play a role in devices such as pacemakers, surgical instruments, and diagnostic equipment. Jackson Spring has supplied components for surgical devices that enhance precision, helping to improve patient outcomes.

The Future of Spring Manufacturing

The future of spring manufacturing technology is promising, driven by AI-powered quality control, predictive analytics, and on-demand customization. These technologies enable manufacturers to produce highly specialized springs efficiently while maintaining stringent quality standards.

Discover how AI is transforming manufacturing.

Actionable Takeaways

For Manufacturers

- Invest in Automation and Materials Science: Advanced machinery and innovative materials are critical for staying competitive.

- Adopt Sustainability Practices: Eco-friendly processes are not just good for the planet—they’re also attractive to customers.

For Purchasing Agents

- Partner with Innovative Suppliers: Work with manufacturers like Jackson Spring who are adopting cutting-edge technologies.

- Consider Total Costs: High-performance springs may have a higher upfront cost but save money in the long run through durability and efficiency.

For Purchasing Agents

Conclusion

Springs may be small, but their impact on technology is immense. At Jackson Spring, we’ve embraced advancements in spring manufacturing technology to provide innovative solutions for industries ranging from automotive to medical devices. Whether you’re a manufacturer or a purchasing agent, leveraging these innovations will help you stay competitive and ensure your products remain reliable and cutting-edge.

By staying informed and proactive, we can collectively shape a future where springs continue to power technological progress in ways we’ve yet to imagine.