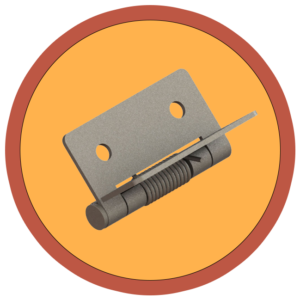

Jackson Spring can develop the right torsion, or double torsion, spring to suit any need or application such as hinges, doors, levers, and various types of machinery.

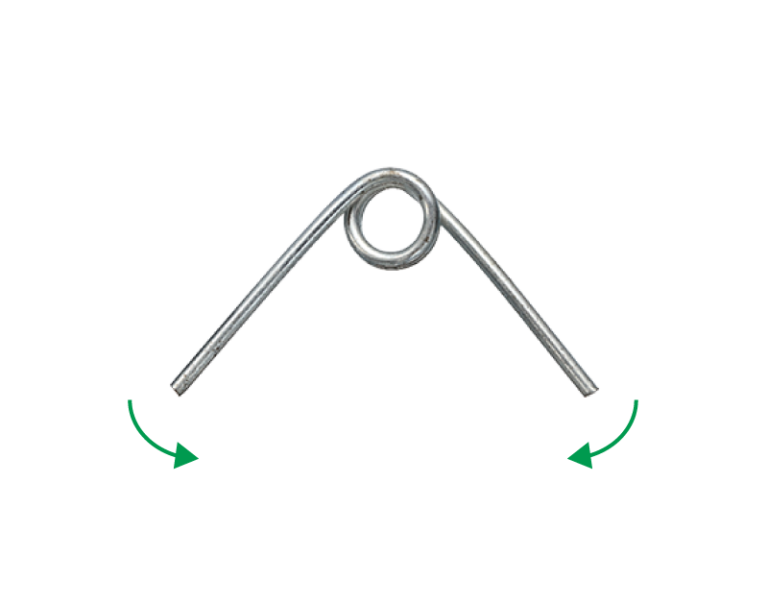

Torsion springs are vital components in mechanical applications, exerting rotational force when twisted around their axis. By storing mechanical energy and providing consistent return force, they enable smooth and balanced rotational movement.

Torsion springs offer versatility in handling various torque loads and angular deflections. Customizable parameters such as wire diameter and coil length ensure they meet specific requirements for garage doors, hinges, and other industrial sectors, delivering precise and controlled rotational force.

With exceptional durability and resilience, torsion springs are constructed from high-quality materials like spring steel or stainless steel. Their robust design withstands repeated twisting cycles while resisting corrosion, fatigue, and wear. Regular maintenance ensures long-lasting reliability, making torsion springs ideal for systems requiring rotational force.

We use SAE and ASTM stainless steel, high carbon steel, and alloy wire.

We can manufacture numerous configurations such as axial, tangential, double torsion, and radial legs with any custom shape.

We can apply surface treatments such as black oxide cleaned & oiled, and zinc plating, to meet both corrosion resistance and aesthetic requirements.