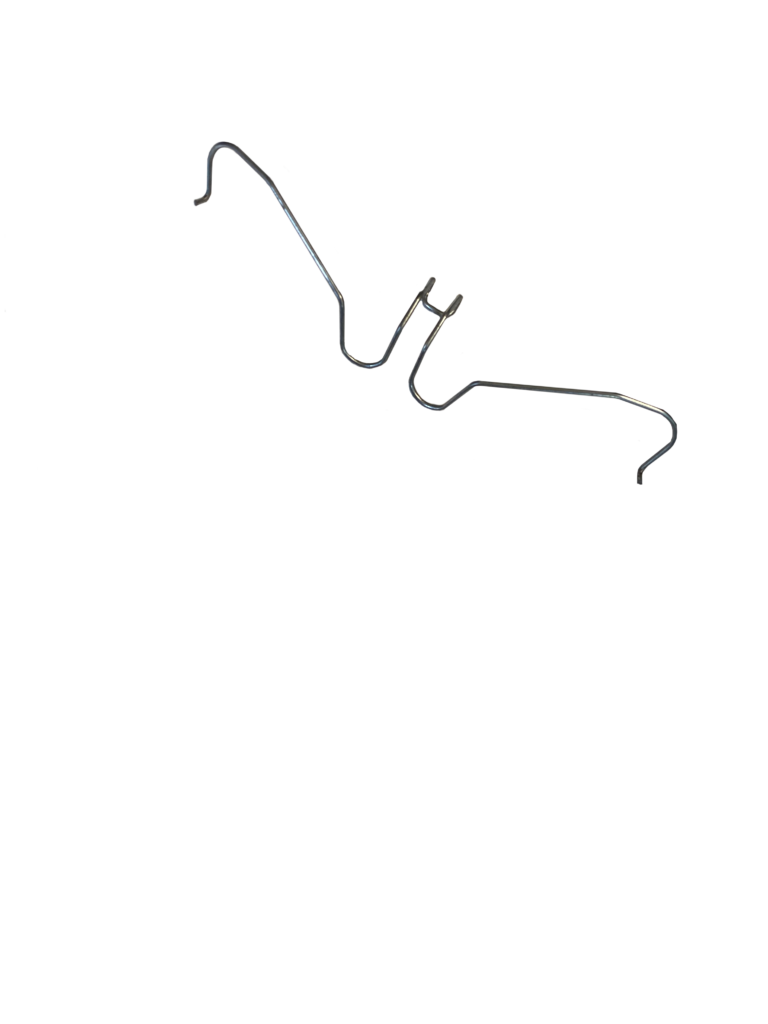

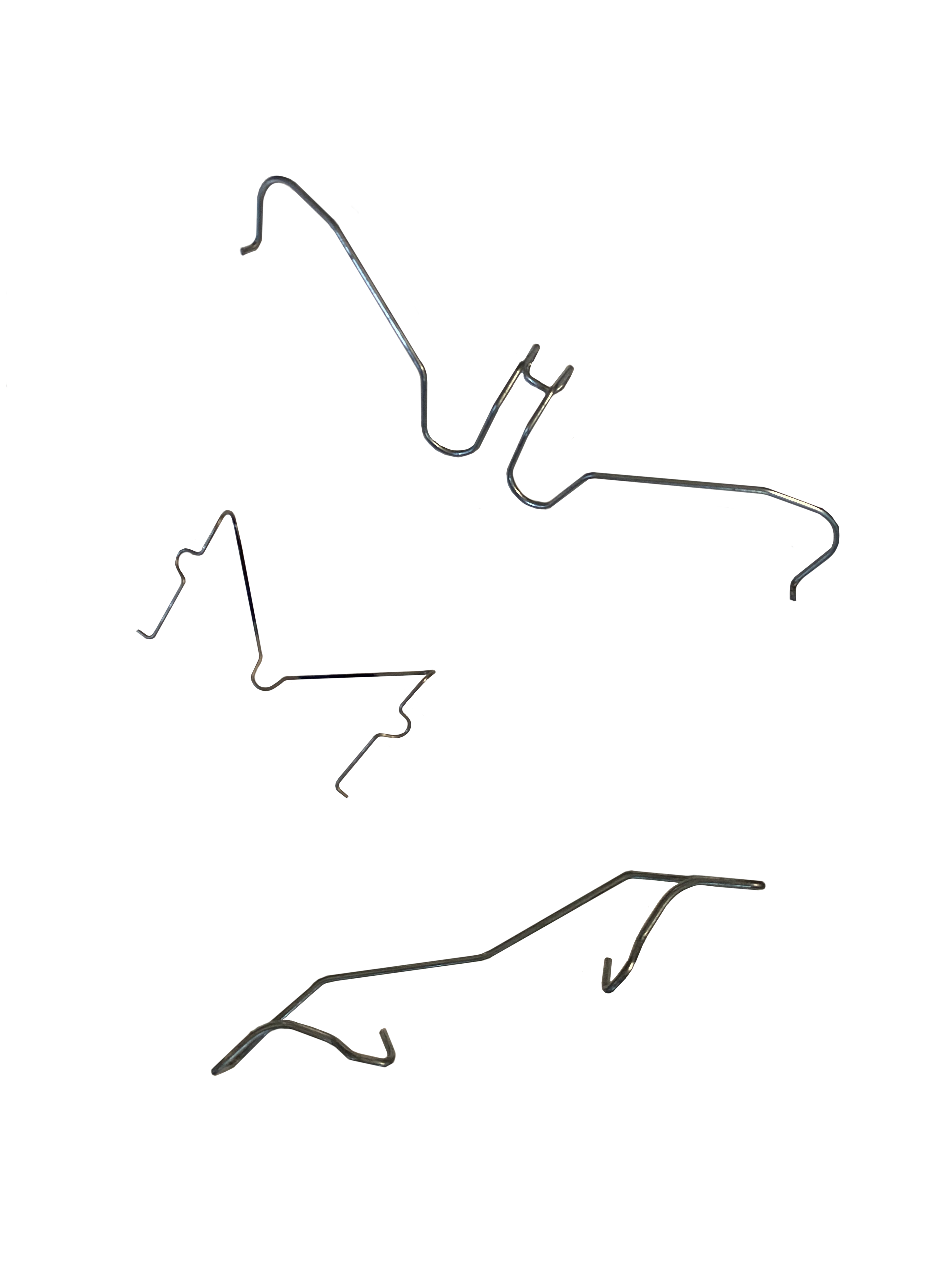

Jackson Spring can develop the right wire form to suit

any need or application such as seating applications, and

cable management.

These forms are created by bending and shaping metal wire into specific configurations, offering a wide range of applications. Whether it’s hooks, clips, brackets, or intricate designs, wire forms provide structural support, attachment points, and functional features in countless mechanical and electrical systems.

By adjusting parameters such as wire diameter, length, and shape, wire forms can be customized to provide optimal strength, tension, or compression characteristics. This flexibility allows wire forms to serve diverse purposes in industries such as automotive, healthcare, electronics, and more.

The robust construction of wire forms ensures long-lasting performance, making them suitable for demanding applications where reliability and longevity are crucial. Additionally, wire forms can be coated or treated to enhance their durability and withstand harsh environments or specific operating conditions.

Our trained metalworkers can create custom wire forms using SAE and ASTM stainless steel, high carbon steel, and alloy wire.

Utilizing manual or CNC processes we can fabricate custom wire forms to customer prints.

We can apply surface treatments include black oxide or zinc plating as well as custom color coating or stainless steel passivation.